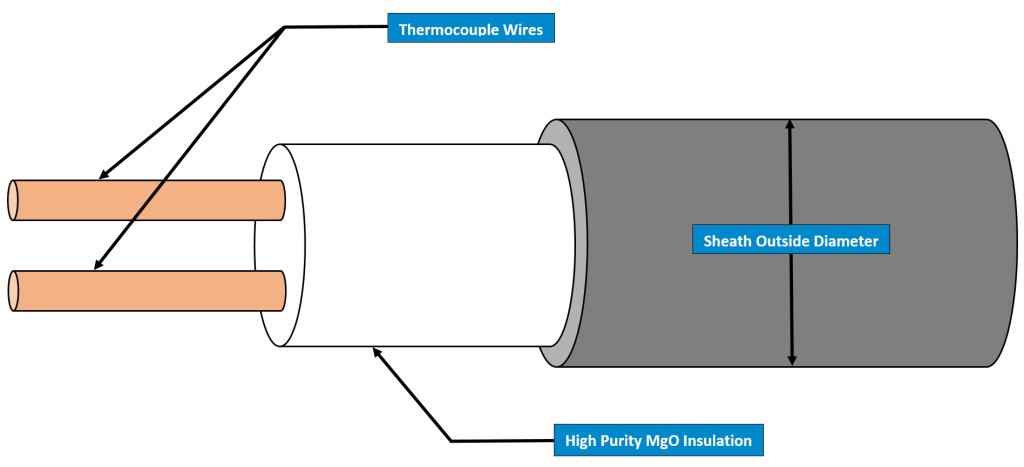

HIGH TEMPERATURE CABLE (MI CABLE)

ARi has developed a complete line of metallic sheath ceramic insulated thermocouple cable for operation in the range of 1100 °C (2012 °F) to 2200 °C (3992 °F). This is a high quality product employing clean room techniques in manufacturing and inspection. It is useable either for fabrication of high temperature thermocouples or leadwire cable for thermocouples.

Electrical Characteristics

| INSULATION RESISTANCE | Room temperature insulation resistance will be a minimum of 1000 megohms at 50 VDC for 1.0-1.5 mm O.D. and 500 VDC for 3.18-6.35 mm O.D. Insulation resistance at 1000 °C will be a minimum of 6100 ohms-meter at 6 VDC. Proper bending will not cause a loss of insulation resistance. |

| WIRE HOMOGENITY | Will be such that a sharp gradient of 800 °C will produce not more than a ± 0.1 millivolt output. |

Physical Characteristics

| FORMABILITY: Forming is limited to a minimum inside bend radius of five (5) sheath diameters for Inconel 600 and Platinum alloys and 10 diameter for Tantalum. | |

| PRESSURE | Can withstand external pressure of 3500 Kg/cm² at room temperature. |

| FABRICATION | AerOpak® can be GTAW welded and brazed without changing insulation resistance. Welding on Tantalum must be done in either vacuum or inert atmosphere. |

| Random lengths will be provided unless requested otherwise. Specific lengths are available in all standard products, up to the maximum single length indicated in the Tables. Length tolerance: ± 15 cm. | |

| Each section of AerOpak® is moisture-sealed at both ends with a suitable resin. When ordering, allow 2.5 cm to be removed from each end. Both ends can be provided with a storage seal (seal welding) in place of the temporary resin seal. | |

| AerOpak® in straight lengths will have a curvature not exceeding six (6) mm in one (1) meter as measured against a straight edge lying free. | |

| DIAMETER | Shall be within ± 0.05mm of nominal. Ovality will not exceed 0.003mm. |

| INTEGRITY | There shall be no porosity, inclusions, pit or scratches which exceed 10% wall thickness, or 0.003 mm (whichever is greater). |

How To Order:

1. Specify by description.

Example: ¼ inch Inconel 600 Sheath, Type R mineral insulated cable.

2. Specify by part number.

The part number is defined per the following:

EXAMPLE

125- 2N - BR-30

| 125 | - | 2 | N | - | B | R | - |

30 |

| (1) | (2) | (3) | (4) | (5) | (6) |

(1) Sheath Diameter = 0.125 inch O.D.

(2) Number of Conductors = 2 wires

(3) Insulation/Purity

N = MgO / 99.4% Min Purity

(4) Sheath Material = Inconel 600

(5) Wire Material = Calibration R

(6) Wire Gage

30 = 30 AWG (0.010 inch)

3. Specify total quantity. If cut lengths are required, specify length of each piece. Accuracy of a cut is +/- 1/2% of the length or +/- 1/2 inch (12.7mm), which ever is larger.

4. Sizes up to 0.375 inch (9.53mm) can be shipped UPS or FedEx.

5. Shipping tolerance for random lengths is +15% / -10% unless specified otherwise.

6. Standard shipping coil sizes and weight:

Shipping Coil Sizes And Weight |

|||||

|---|---|---|---|---|---|

| Sheath O.D. | Coil O.D. | Approximate Weight at 100 ft (30.48 meters) | |||

| inch | mm | inch | mm | lbs | kg |

| 0.020 | 0.5 | 20-22 | 508-559 | 0.2 | 0.09 |

| 0.040 | 1.0 | 0.3 | 0.14 | ||

| 0.062 | 1.6 | 30 | 762 | 0.9 | 0.41 |

| 0.120 | 3.0 | 2.5 | 1.13 | ||

| 0.125 | 3.2 | 3.3 | 1.50 | ||

| 0.188 | 4.8 | 7.0 | 3.18 | ||

| 0.236 | 6.0 | 42 | 1067 | 10.8 | 4.90 |

| 0.250 | 6.4 | 12.3 | 5.58 | ||

| 0.313 | 8.0 | 19.5 | 8.85 | ||

| 0.375 | 9.5 | 27.0 | 12.25 | ||

| 0.500 | 12.7 | 42-48 | 1067-1220 | 50.0 | 22.68 |

| 0.625 | 15.9 | Shipped straight , 20 ft maximum lengths | Shipped straight , 6.1 meters maximum lengths | 75.0 | 34.02 |

| 0.750 | 19.0 | 112.5 | 51.03 | ||

MATERIAL SPECIFICATIONS

Standard Sheath Material |

|||||||

|---|---|---|---|---|---|---|---|

| Sheath Material | ARi Symbol | Maximum Usage Temperature | Melting Temperature | Environment | Minimum Bend Radius | ||

| °F | °C | °F | °C | ||||

| Inconel 600* | B | 1175 | 1345 | Inert, Vacuum, Oxidizing | 5x Diameter | ||

| Platinum 10% Rhodium | AH | 1550 | 1850 | Inert, Oxidizing | 5x Diameter | ||

| Tantalum | N | 2200 | 2995 | Inert, Vacuum | 10x Diameter | ||

| 310 ST/ST | D | 1050 | Inert, Vacuum, Oxidizing | 5x Diameter | |||

| Niobium 1% Zirconium | AV | 2200 | 2495 | Inert, Vacuum | 10x Diameter | ||

*Registered U.S. Trademark, International Nickel Corp.

Thermocouple Wire |

|||

|---|---|---|---|

| Material | ASTM E-230-81 Symbol | ARi Symbol | Calibration Tolerance Limits Of Error |

| Platinum 13% Rhodium vs. Platinum | R | R | ± 1.5 °C from 0 to 600 °C |

| ± 25% from 600 to 1450 °C | |||

| Platinum 10% Rhodium vs. Platinum | S | S | |

| Platinum 30% Rhodium vs. Platinum 6% Rhodium | B | B | ± 0.5% from 800 to 1700 °C |

| Tungsten 5% Rhenium vs. Tungsten 26% Rhenium | --- | AE | ± 4.44 °C from 0 to 427 °C |

| ± 1% from 427 to 2315 °C | |||

Please contact us for further information or any special requirements you may have.

Standard AerOpak® Mineral Insulated Cable is normally available from our inventory for immediate shipment. Call or email for details!

We want to hear from you:

800-237-6725 (Toll Free)

630-953-9100 (Phone)

630-953-0590 (Fax)

sales@ariindustries.com