- Require Consultation?

- Contact Us Now

Thermocouples are probably the most popular temperature sensors in use today. Basic models are relatively accurate, low cost, interchangeable, and can measure a wide range of temperatures. Accurate temperature measurement is one of the most common tasks faced by professionals in modern industrial and control design.

| Platinum 10% Rhodium | Expensive, chemically stable, good mechanical properties, must be protected in use, not suitable for low temperature applications. |

| Platinum 13% Rhodium | Expensive, chemically stable, good mechanical properties, may be used in oxidizing atmospheres, must be protected in use, not suitable for low temperature applications. |

| Platinum 20% Rhodium | Very expensive, for use in temperature ranges beyond the capabilities of the above noble metals. |

| Iron-Constantan | Low cost, suitable for oxidizing or reducing atmospheres. Subject to chemical attack. |

| Copper-Constantan | Suited to ambient temperatures, similar to the model above. |

| Chromel-Alumel | Higher temperature range (1000-2000°F). Can be used in an oxidizing atmosphere, is mechanically strong, and is resistant to chemical attack. |

| Chromel-Constantan | Very stable, not to be used in reducing atmospheres, subject to chemical attack. |

The thermocouple wires are welded together and the insulation is sealed against penetration by liquid or gas. This type of thermocouple offers the least protection and is best suited to ambient atmospheres.

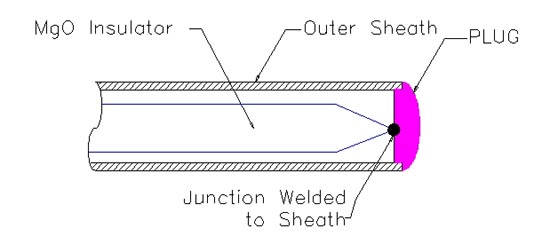

The thermocouple wires are welded together with (grounded to) the sheath. This provides more protection, and is used in cases where an exposed junction would not work due to harsh atmospheric conditions, or when longer life is required.

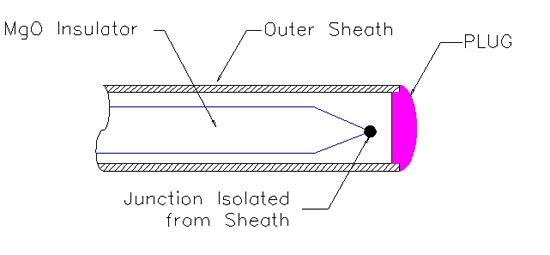

The thermocouple wires are welded together and are insulated from the sheath. This provides the most protection for the thermocouple elements and is recommended for the longest life. Different types of sheath materials (protection tubes) offer greater protection depending on the conditions.

the conditions.

Standard AerOpak® Mineral Insulated Cable is normally available from our inventory for immediate shipment. Call or email for details!

US manufacturer with in-house capability to produce custom Mineral Insulated Cables, Thermocouple, RTDs, and Heaters.

+1 (800) 237-6725 (Toll Free)

+1 (630) 953-9100 (Phone)

381 Ari Court

Addison, Illinois 60101

Sign up our newsletter to get update information, news and free insight.