It's EASY, get a quote within 2-days!

HIGH TEMPERATURE THERMOCOUPLE

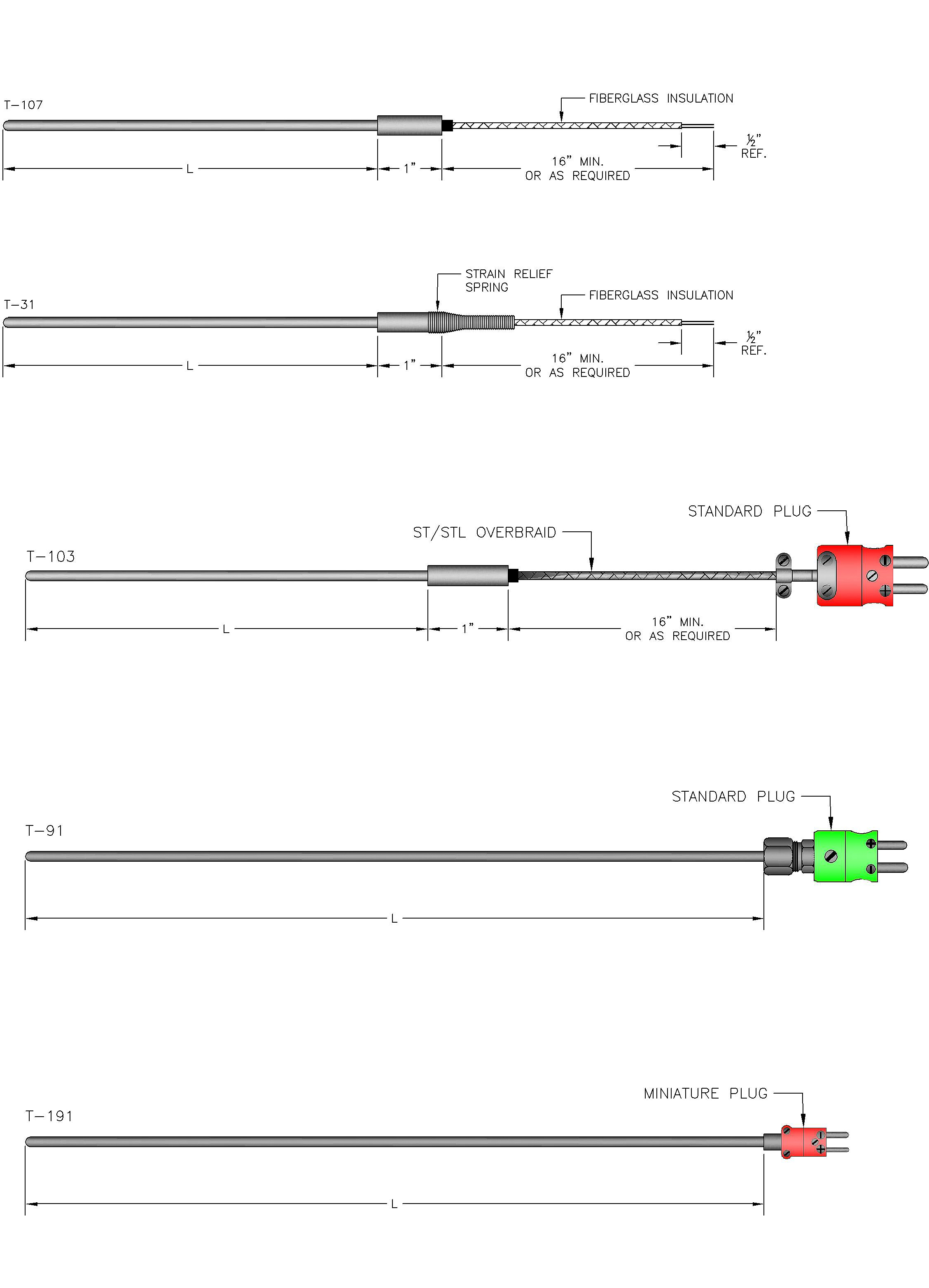

ARi High Temperature Thermocouple is used in applications where base metal thermocouples cannot be used because of excessive temperatures or severe atmosphere. ARi can provide a wide variety of wire combinations and sheath materials to meet the harshest demands. By selecting certain materials, temperature measurements up to 2300°C can be achieved.

ARi manufactures it's own mineral insulated cable and many of our high temperature thermocouple are available in bendable sheath and longer lengths. This in-house capability enables us to manufacture a variety of custom material combinations. Applications include;

- Process control of vacuum furnaces

- Gas furnaces

- High temperature ovens

- Reaction furnaces

Processes include sintering, annealing and carburizing. While many process variables affect service life, there are two (2) important considerations for selecting the proper thermocouple for a particular application.

- What is the temperature range you will need to measure?

- What is the atmosphere the thermocouple will be exposed to during operation?

With this information, it is possible to use these tables to select a suitable wire, sheath and insulation combination. The physical requirements of the thermocouple (sheath diameter, junction type and termination style) can then be selected to complete the design. Of course, you can always contact our ARi sales staff for help in selecting the proper high temperature thermocouple.

Material Specifications

Sheath Materials |

||||||

|---|---|---|---|---|---|---|

| Sheath Type | ARi Symbol | Maximum Temp (°C) | Melting Temp (°C) | Allowable Environment | Standard Sheath Diameter (inches) | Minimum Bend Radius |

| Inconel 600 | B | 1175 | 1345 | Inert, Vacuum, Oxidizing | 0.040, 0.062, 0.125, 0.188, 0.250 | 5X Sheath Diameter |

| Platinum 10% Rhodium | AH | 1550 | 1850 | Inert, Oxidizing | 0.040, 0.062, 0.125 | 5X Sheath Diameter |

| Tantalum | N | 2200 | 2995 | Inert, Vacuum | 0.040, 0.062, 0.125 | 10X Sheath Diameter |

| Niobium 1% Zirconium | AV | 2200 | 2495 | Inert, Vacuum | 0.062, 0.125 | 10X Sheath Diameter |

| Molybdenum | O | 2000 | 2620 | Inert, Vacuum, Reducing | 0.062, 0.125, 0.188, 0.250 | Do Not Bend |

| Coated Molybdenum | OCR | 1600 | 2000 | Inert, Oxidizing | 0.125, 0.250 | Do Not Bend |

Wire Types |

||||

|---|---|---|---|---|

| Thermocouple Combinations | Calibration Type | ARi Symbol | Standard Limits Of Error | Recommended Temperature Range |

| Platinum 30% Rhodium (+) Vs. Platinum 6% Rhodium (-) | B | B | ± 0.5% | 870 - 1700 °C |

| Tungsten 5% Rhenium (+) Vs. Tungsten 26% Rhenium (-) | C | AE | ± 4.4 °C (0 - 426 °C)* | 0 - 2200 °C |

| ± 1% (426 - 2315 °C)* | ||||

| Tungsten 3% Rhenium (+) Vs. Tungsten 25% Rhenium (-) | D | AO | ± 4.4 °C (0 - 426 °C)* | 0 - 2200 °C |

| ± 1% (426 - 2315 °C)* | ||||

| Platinum 13% Rhodium (+) Vs. Platinum | R | R | ± 1.5 °C or 0.25% ** | 0 - 1450 °C |

| Platinum 10% Rhodium (+) Vs. Platinum | S | S | ± 1.5 °C or 0.25% ** | 0 - 1450 °C |

*Per ASTM E-988

**Per ASTM E-230

Insulation Materials |

||||

|---|---|---|---|---|

| Insulation Type | ARi Symbol | Maximum Operating Temp (°C) | Approximate Melting Temp (°C) | Comments |

| Magnesia (MgO) | N | 1700 | 2800 | Very hydroscopic. Used mostly in compacted sheaths. |

| Alumina Oxide (Al²O³) | A | 1550 | 2040 | Excellent with Platinum alloys. |

| Hafnium Oxide (HfO²) | H | 2200 | 2790 | Comparable to Beryllium Oxide and safe to handle. |

| Beryllium Oxide (BeO)*** | B | 2200 | 2650 | Excellent High Temperature thermal conductivity and resistivity. |

***Beryllium is considered a toxic material and can cause health problems if particles are inhaled.

Options / Modifications

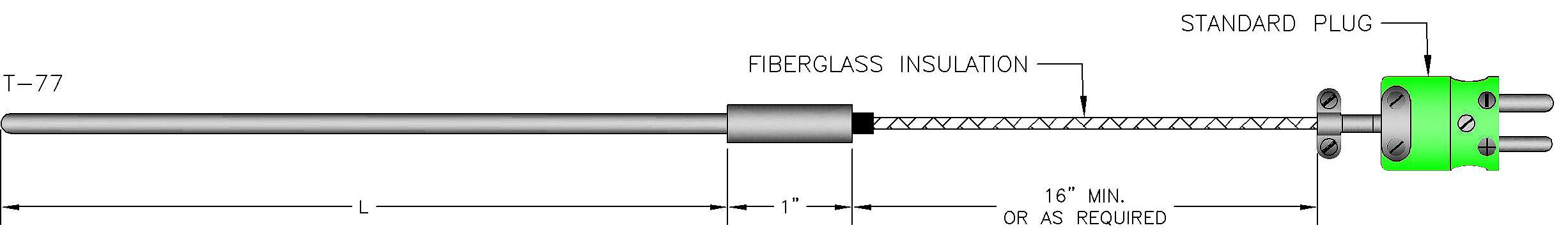

HIGH TEMPERATURE TERMINATION

In applications where cold end termination will see temperatures in excess of 200ºC, standard epoxy seals may breakdown causing failure. In this case ARi can supply a ceramic cement seal which can withstand temperatures up to 450ºC.

To specify this option, add the prefix HI- in front of the part number selected.

Example: HI-T-107N-12DAE(9.5)N

DUPLEX ELEMENT CONSTRUCTION

Most high temperature thermocouple combinations with an outside sheath diameter of 1/8" or larger are available in duplex element construction (2 separate measuring circuits in 1 sheath).

To specify this option, add the suffix .4 after the style number and "repeat the junction code a second time and add parentheses".

Example: T-91.4N-12FR(9.9)B or T-91.4B-18DAE(9.3)(9.3)O

MATING JACK

If required with any of our male plug type thermocouples (T-91, T-191, and HI-T-91), we can supply the appropriate mating jack with the assembly.

To specify this modification, add (MOD) after the part number and specify "Supplied With Mating Jack" .

ARGON BACKFILL

In order to minimize the effects of any residual oxidation remaining inside non-compacted sheath designs, ARi can evacuate and backfill the sheath with inert Argon gas prior to sealing the cold end.

To specify this modification, add (MOD) after the part number and specify "With Argon Backfill" in the description.

SPECIAL LIMITS OF ERROR

High temperature Thermocouple with R, S & B calibrations made with mineral insulated construction can be supplied with special limits of error tolerances per ASTM E-230 or Class 1 per IEC-584 subject to availability of material from stock.

To specify this modification, add (MOD) after the part number and specify "Per Special Limits of Error" or "Per Class 1 Tolerance" in the description.

TEFLON INSULATED EXTENSION WIRES

For designs where extension wire attachment is required, we can supply moisture resistant Teflon insulated extension wire in place of our standard fiberglass. Other insulation types can be supplied subject to availability.

To specify this modification, add (MOD) after the part number and specify "With Teflon Insulated Leads" in the description.

Ordering Information

ARi Part Numbering Symbols/Codes |

|||||||

|---|---|---|---|---|---|---|---|

| Wire Type | Symbol | Sheath Type | Symbol | Insulation Type | Symbol | Sheath Diameter (inches) | Code |

| S | S | Inconel 600 | B | Magnesia (MgO) | N | 0.040 | A |

| R | R | Platinum 10% Rhodium | AH | Alumina Oxide (Al²O³) | A | 0.060 | (.060)* |

| B | B | Tantalum | N | Hafnia Oxide (HfO²) | H | 0.062 | B |

| C | AE | Molybdenum | O | Beryllia Oxide (BeO) | B | 0.118 | (.118)* |

| D | AO | Niobium 1% Zirconium | AV | 0.125 | D | ||

| Coated Molybdenum | OCR | 0.177 | (.177)* | ||||

| 0.188 | E | ||||||

| 0.236 | (.236)* | ||||||

| 0.250 | F | ||||||

*Non-standard/ metric size.

Junction Number Codes |

||||

|---|---|---|---|---|

| Sheath Type | Wire Type Letter Code | Insulation Type Letter Code | GROUNDED - Junction Code | UNGROUNDED - Junction Code |

| Inconel 600 | R, S, B | N | (8.1) | 9 |

| Platinum 10% Rhodium | R, S, B | N | 8 | 9 |

| Coated Molybdenum | AE, AO | A | N/A | (9.4) |

| AE, AO | N, H, B | N/A | (9.3) | |

| Tantalum | R, S, B | A | (8.1) | (9.4) |

| R, S, B | N, H, B | (8.1) | (9.5) | |

| AE, AO | H, A | (8.1) | (9.3) | |

| AE, AO | N, B | (8.1) | (9.5) OR (9.3)* | |

| Molybdenum | R, S, B | A | N/A | (9.4) |

| R, S, B | N, H, B | N/A | 9 | |

| AE, AO | N, H, B, A | N/A | (9.3) | |

* Assembly style.

HOW TO ORDER WIRE AND PLUG ASSEMBLIES:

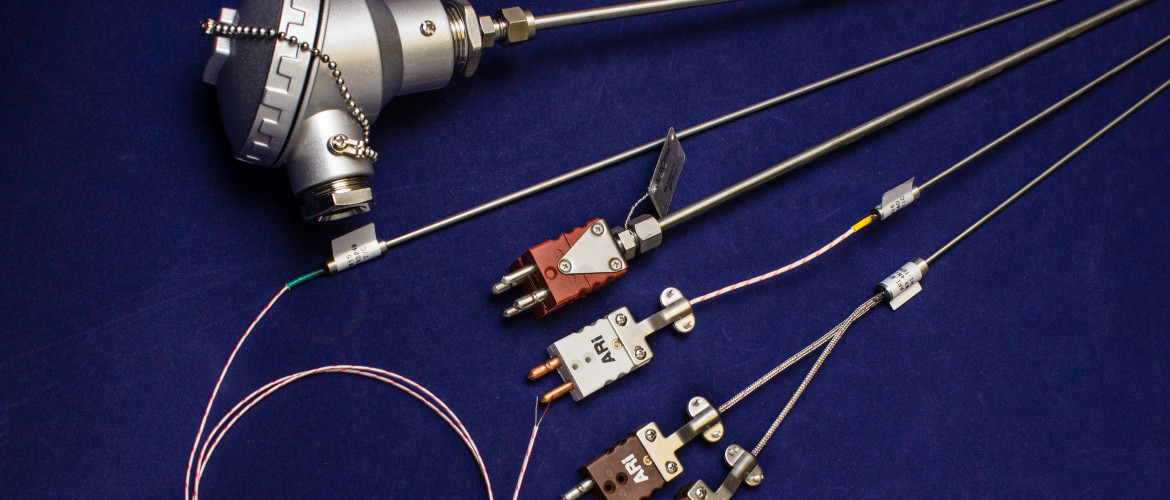

Example part number of a high temperature thermocouple: T-77N-24DAE(9.3)O-16

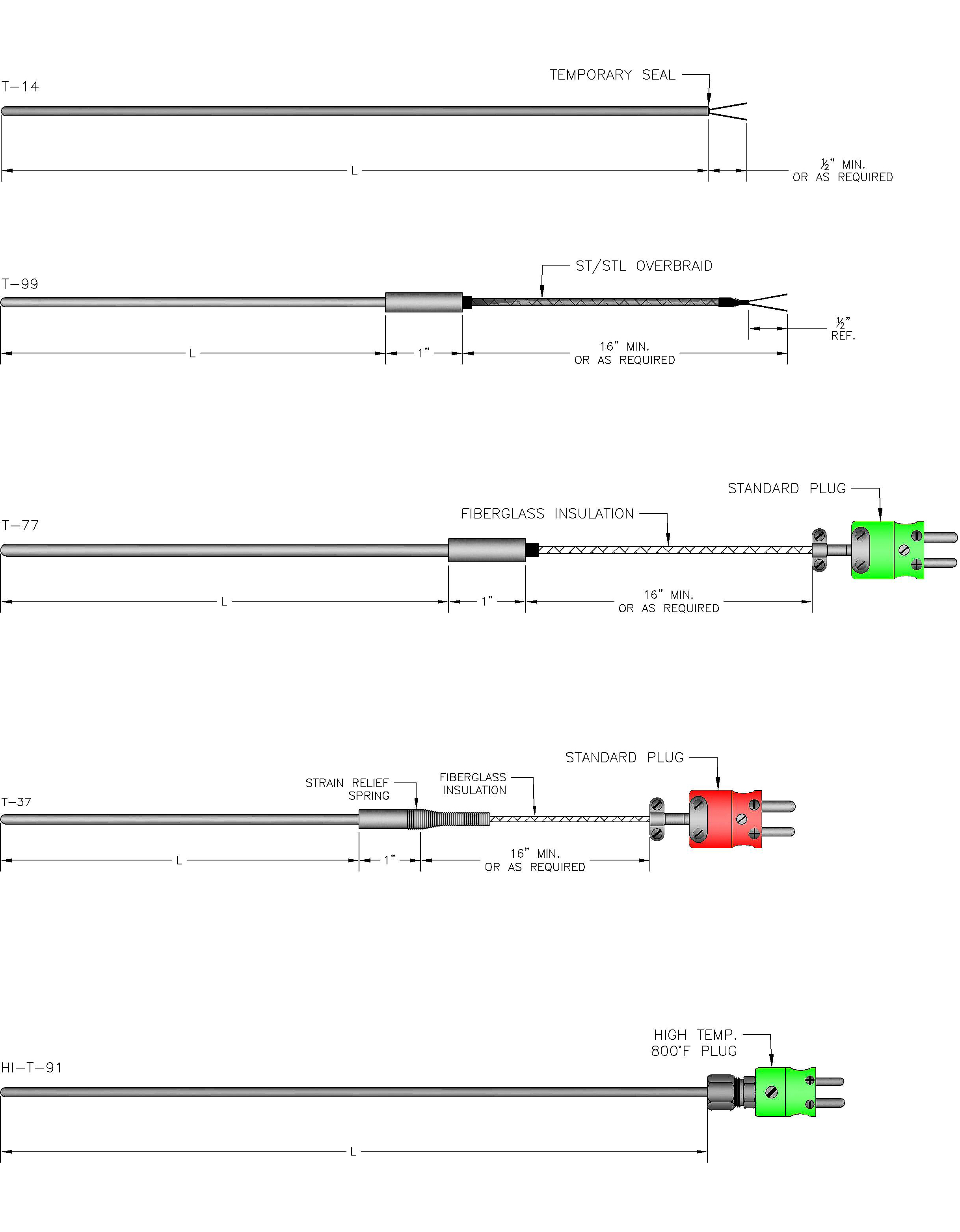

- Style Number: T-77

- Insulation Material: N - 99.4% min MgO purity

- Sheath Length "L" in inches: 24 inches

- Sheath Diameter: D - 0.125 inch

- Wire Calibration: AE - Type C wire

- Hot Junction: (9.3) - Ungrounded

- Sheath Material: O - Molybdenum

- Extension Wire Length "A" in inches: 16 inches